Evaluation Analysis

- TOP

- Core Technology

- Evaluation Analysis

Evaluation Analysis

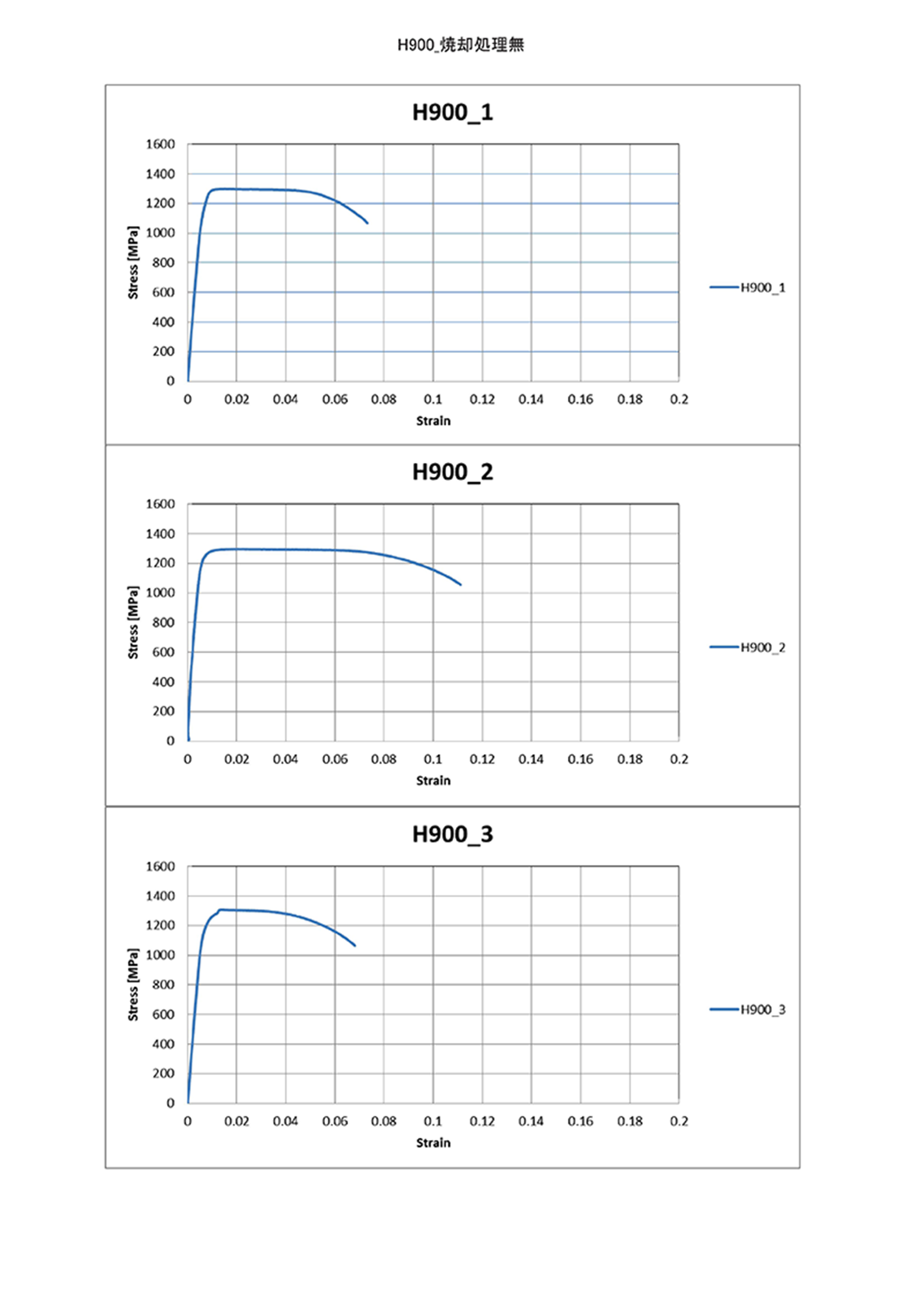

Evaluation and analysis technologies and equipment are neccessary for micro precision processing.

Introduction of evaluation equipment

-

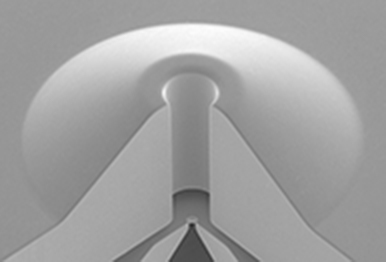

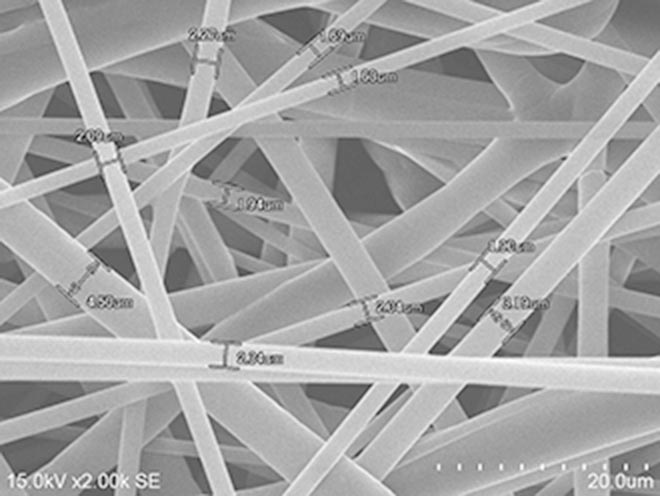

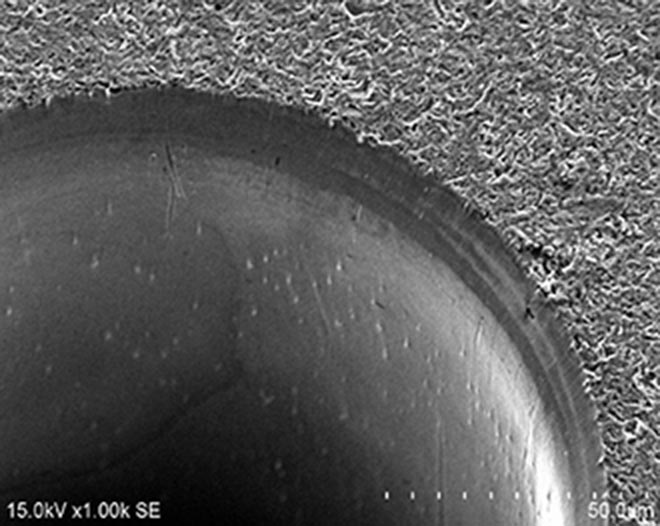

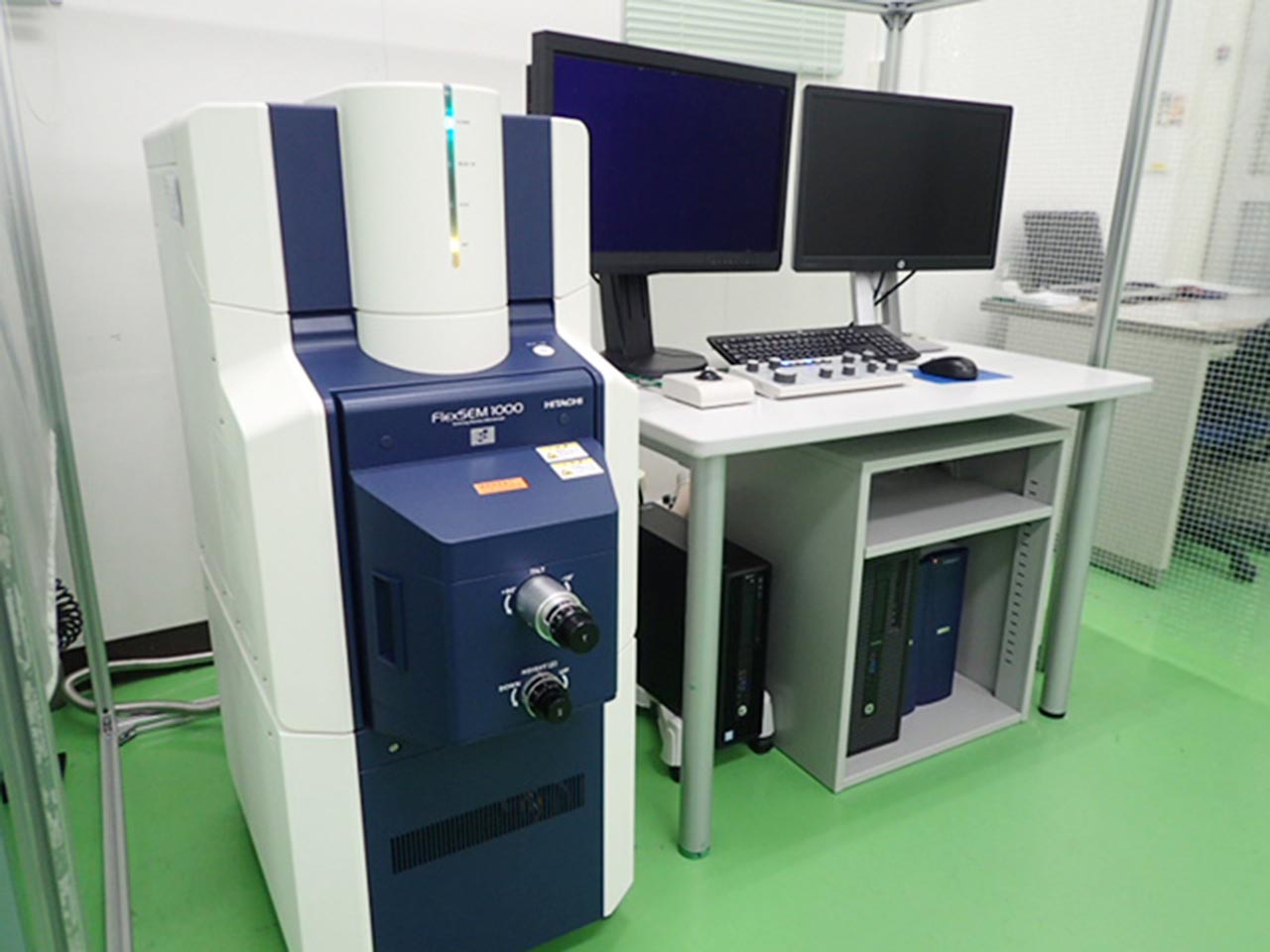

FE-SEM(2台)

FE-SEM(2台)

-

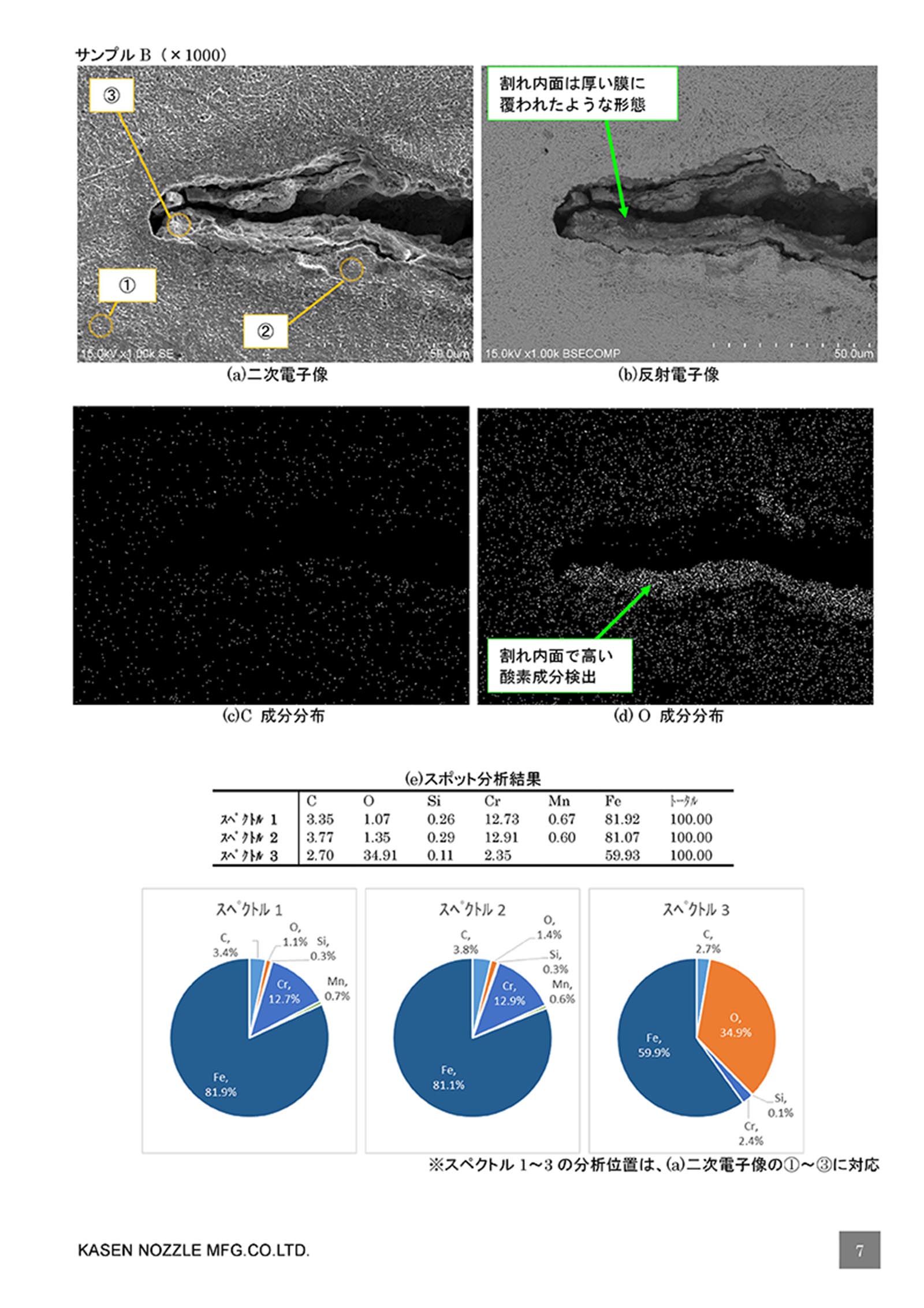

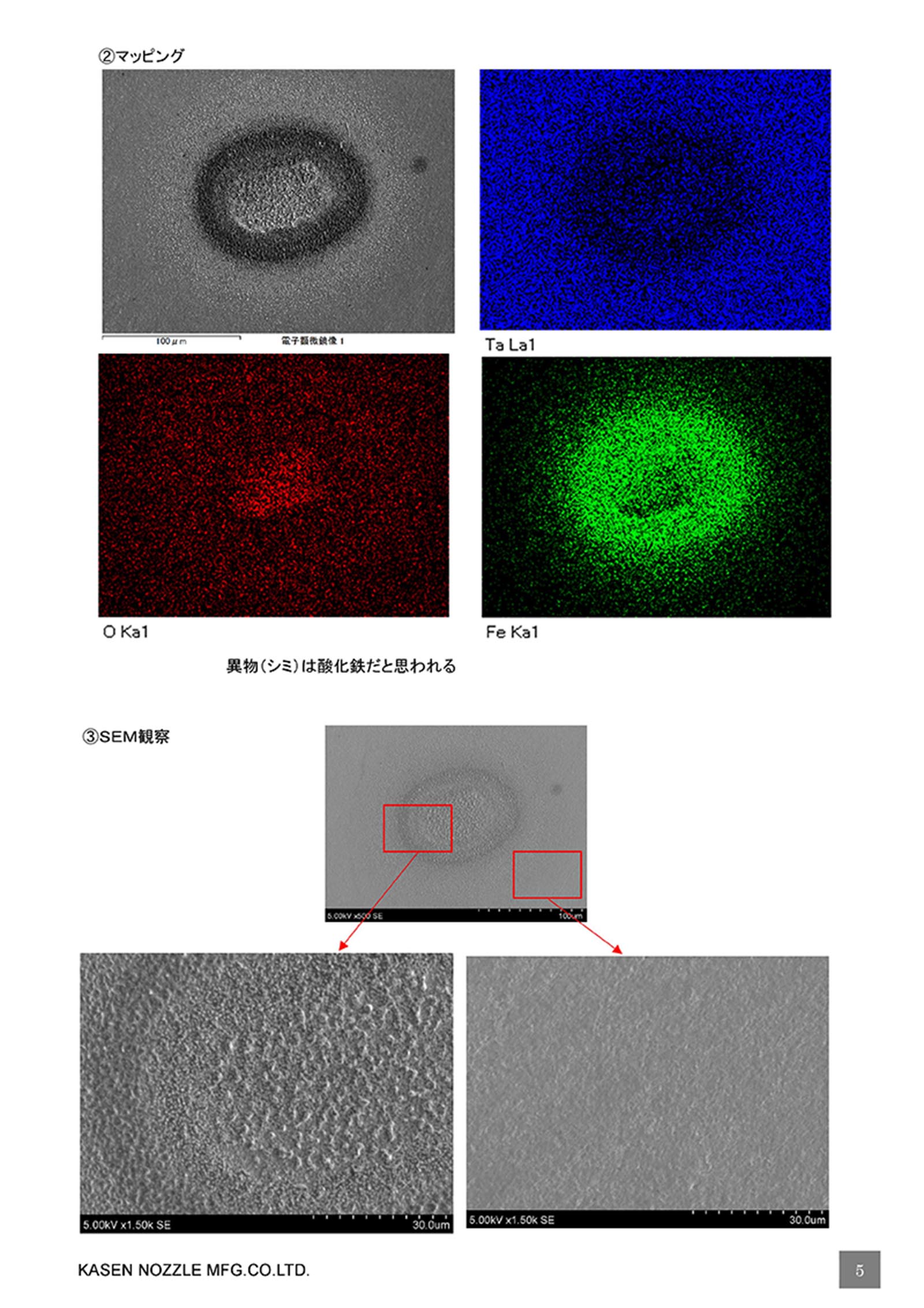

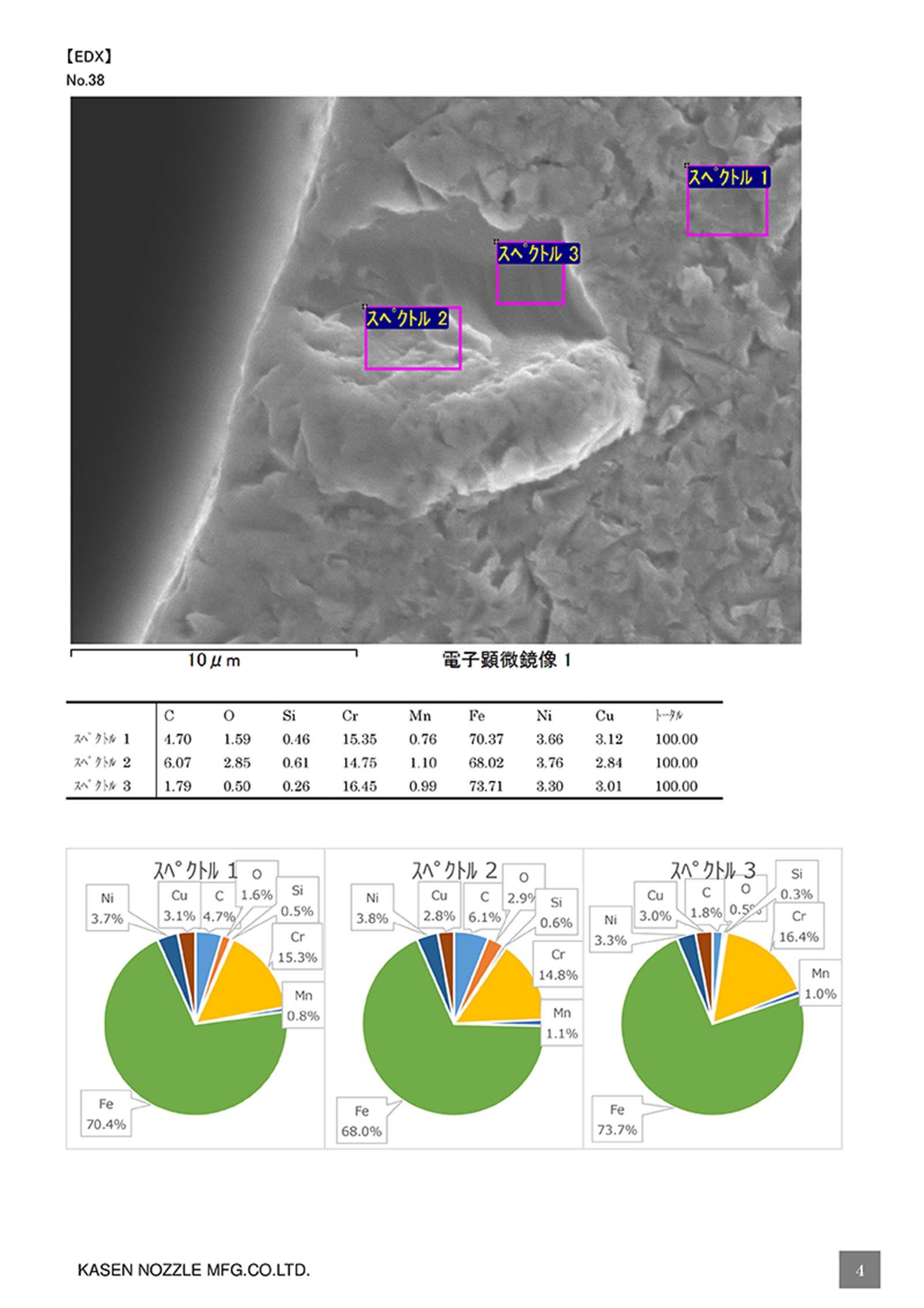

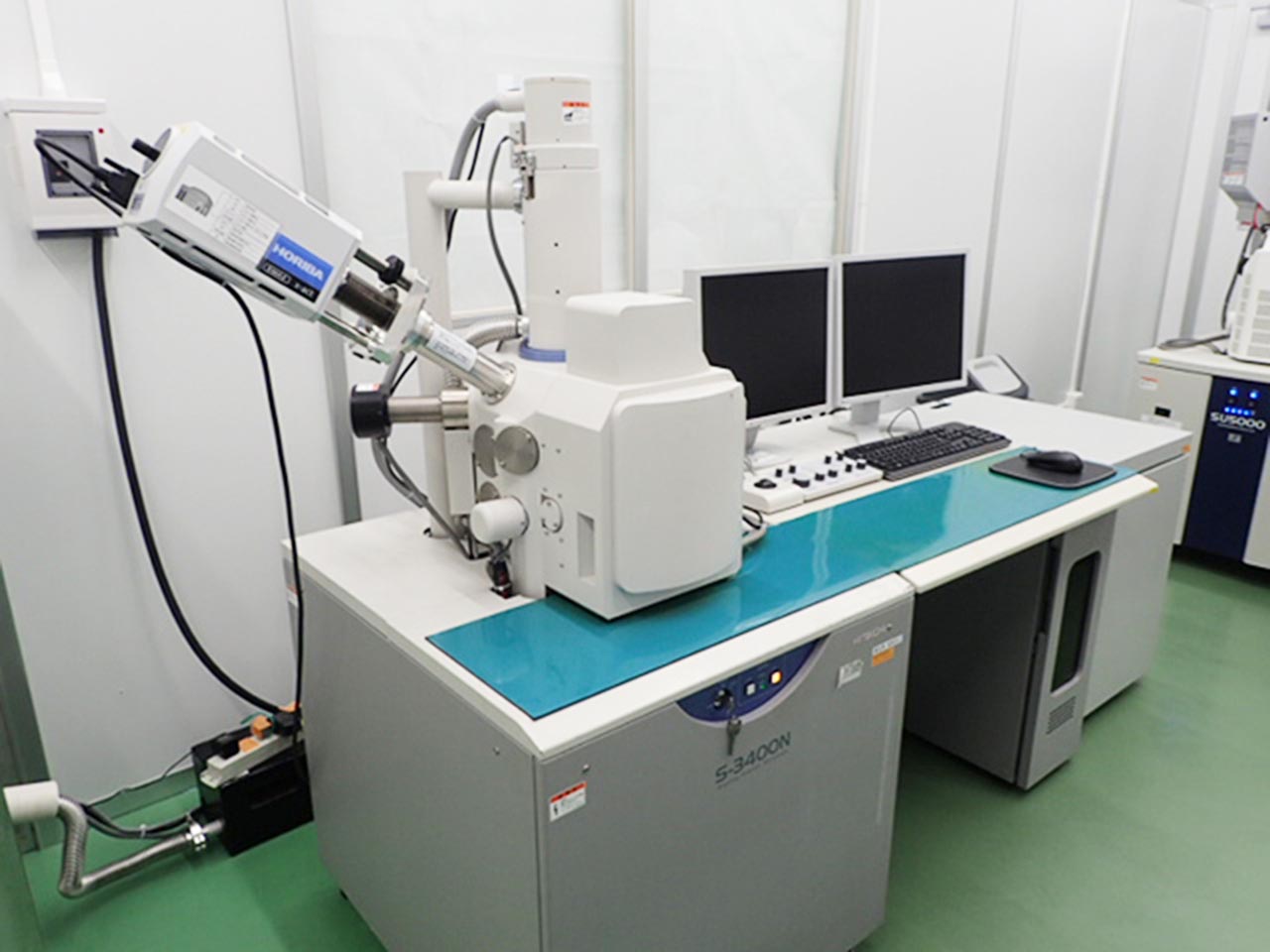

SEM(EDX)

SEM(EDX)

-

SEM(EDX)

SEM(EDX)

-

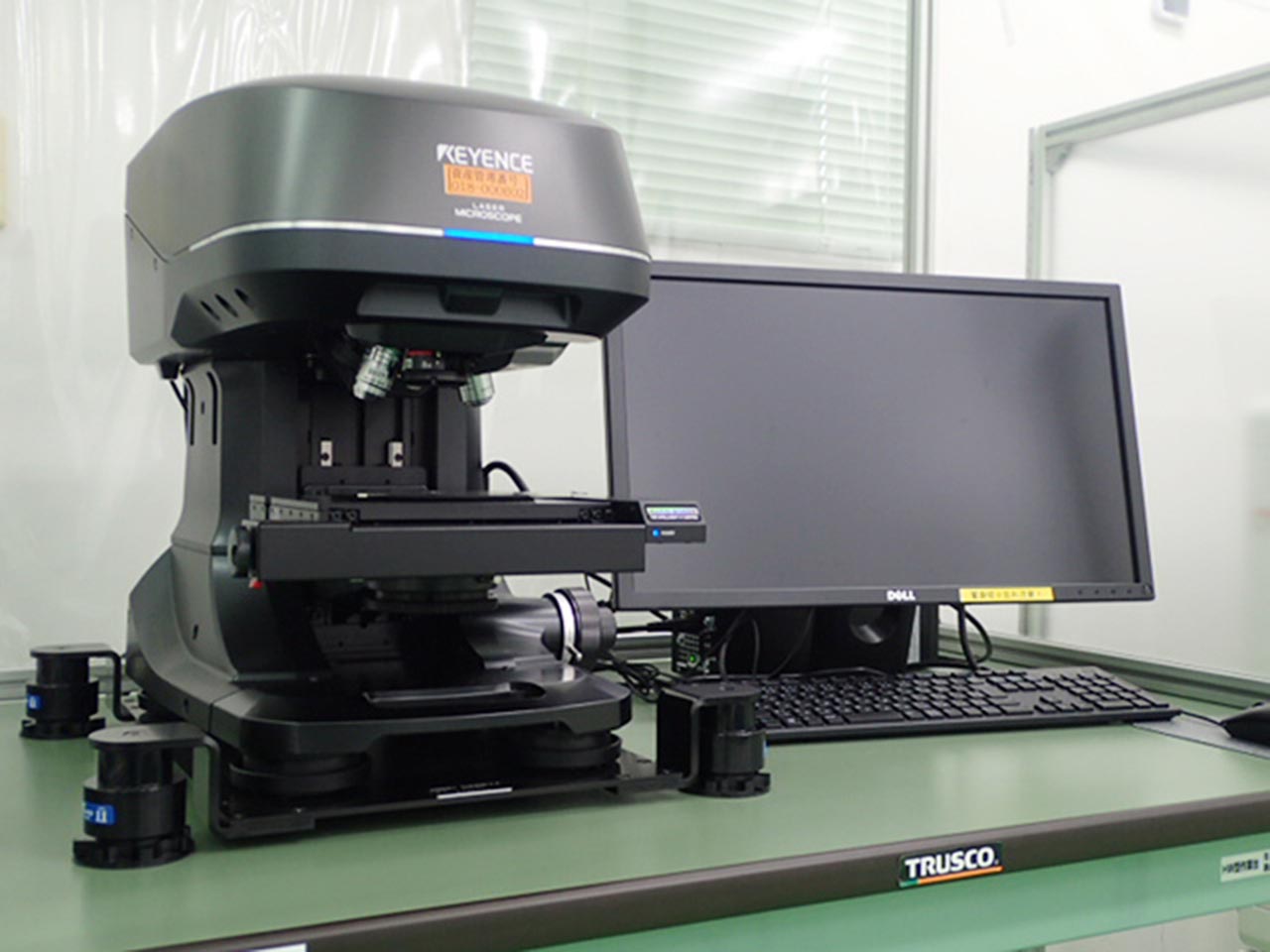

Laser Microscope

Laser Microscope

-

Image dimension measuring machine

Image dimension measuring machine

-

Digital Microscope

Digital Microscope

-

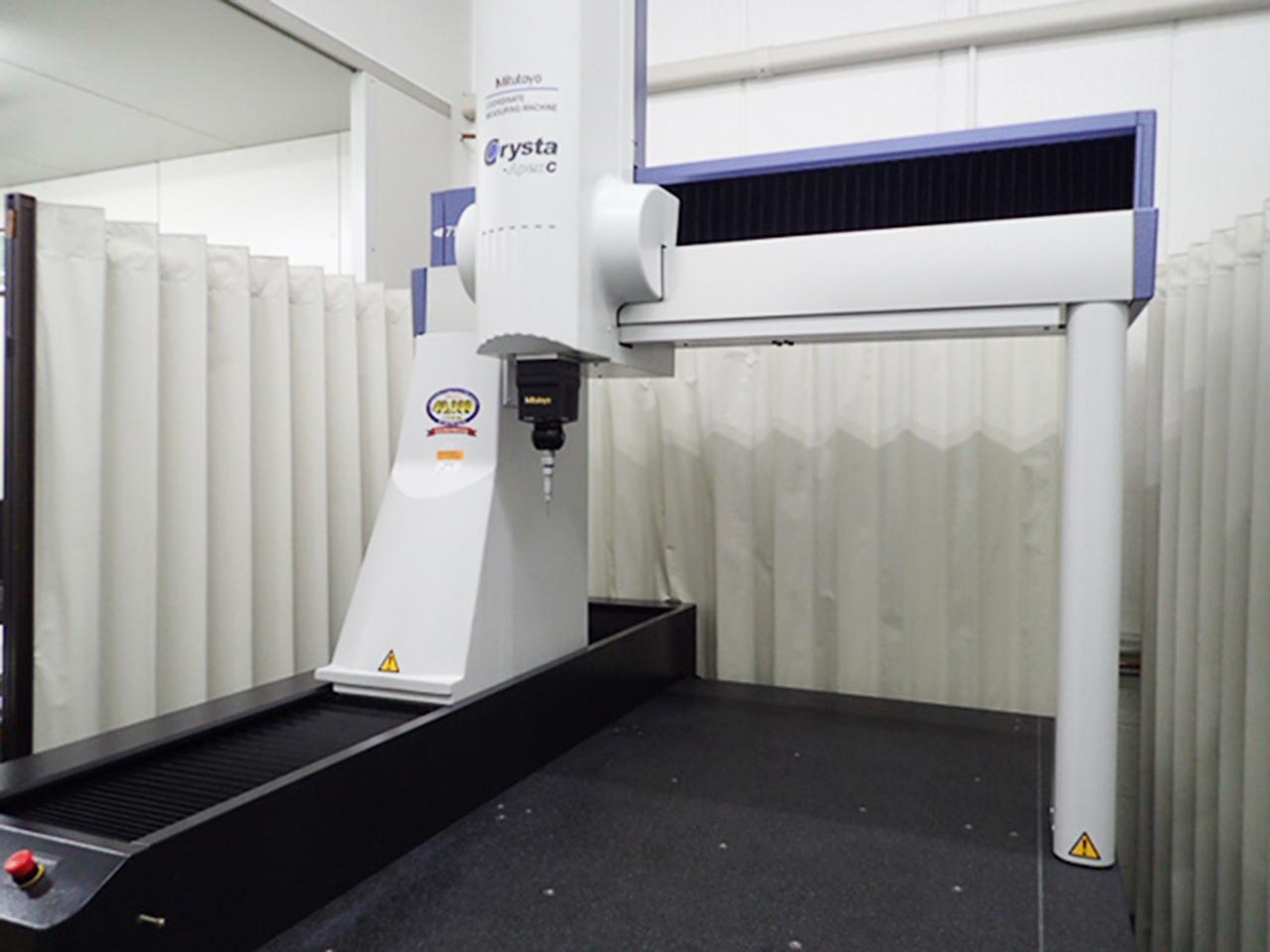

3D Measuring machine

3D Measuring machine

-

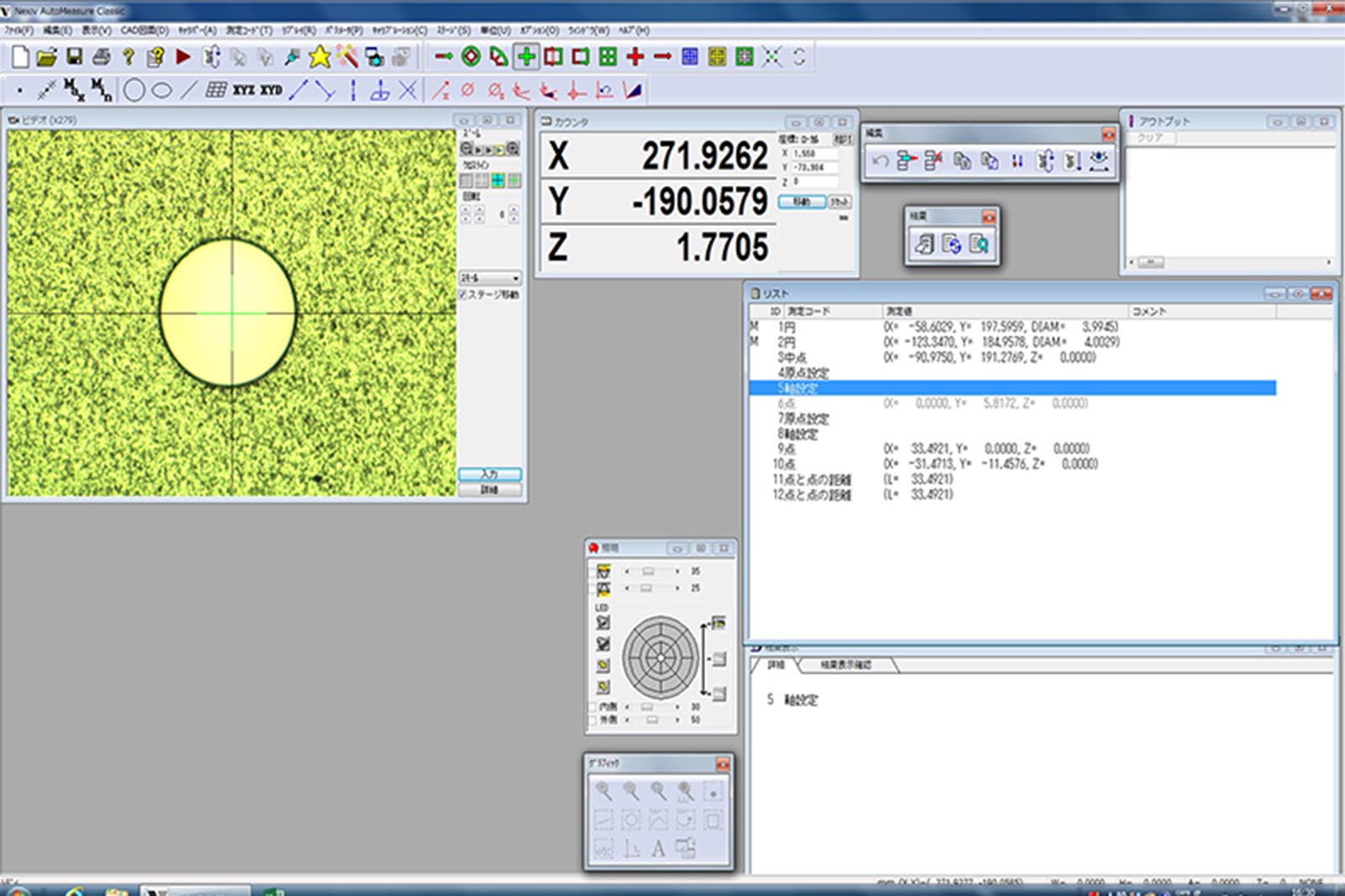

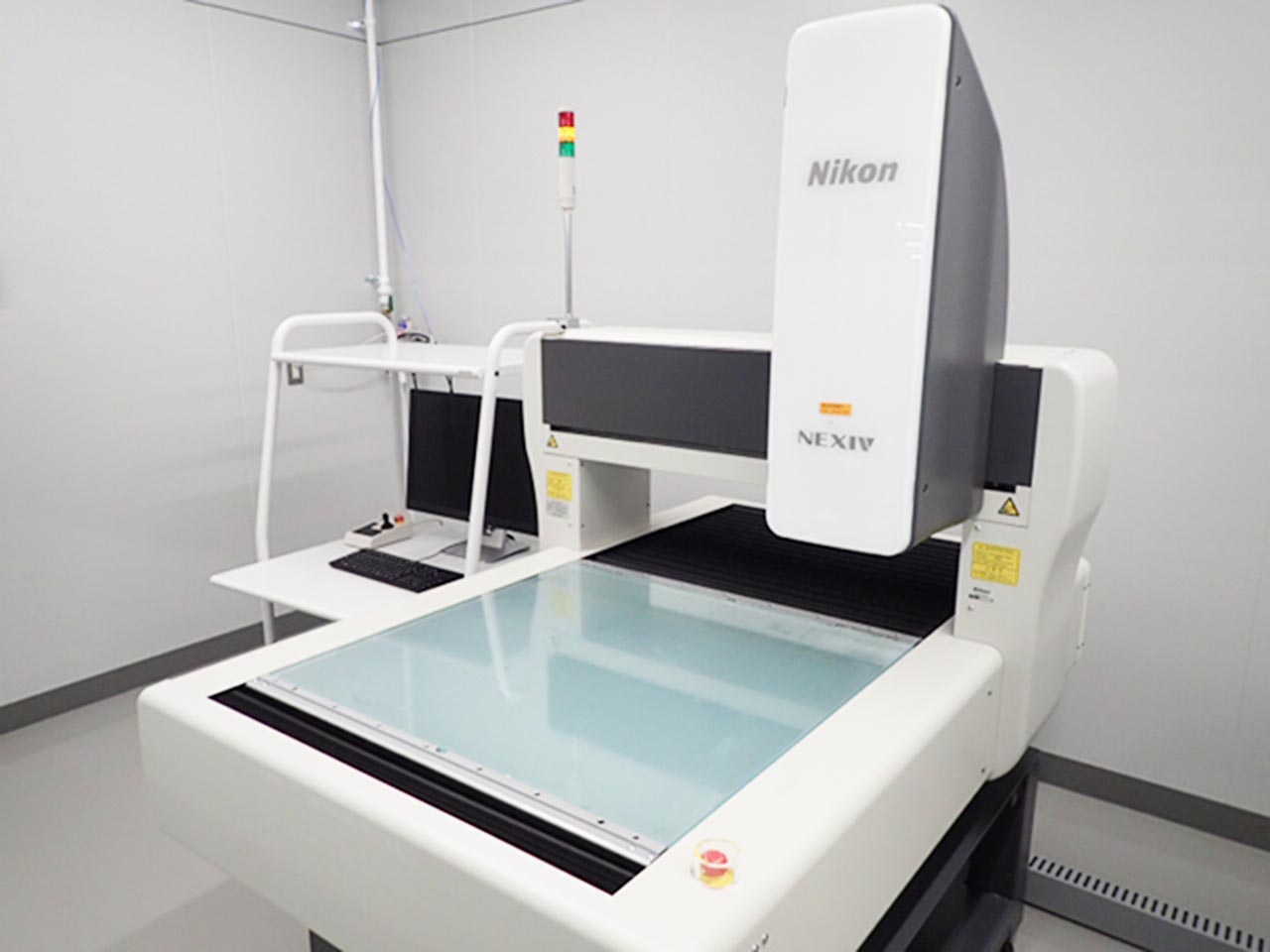

CNC Image measuring machine

CNC Image measuring machine

■Other

| Equipment name | Number of units |

|---|---|

| Infrared microscope | 1 |

| Measuring microscope | 15 |

| Stereo microscope | 75 |

| Flow measuring instrument | 3 |

| Leak detectors | 1 |

| Equipment name | Number of units |

|---|---|

| Rockwell hardness tester | 1 |

| Micro vickers hardness tester | 1 |

| Surface roughness gauge | 2 |

| Measuring projectors | 14 |

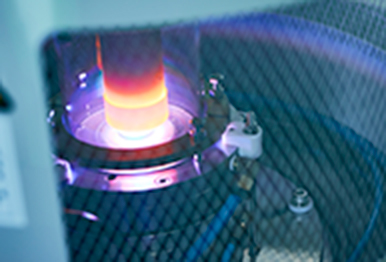

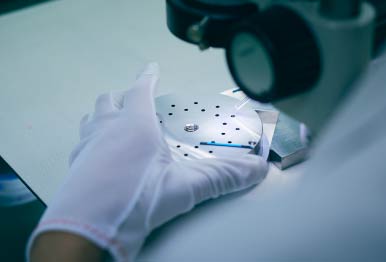

Precision cleaning

Products that require a high level of cleanliness, such as parts for semiconductor manufacturing equipment, are precision cleaned using a pure water ultrasonic cleaner in a class 1000 or lower clean room or local clean boot. Inspection using optical and electronic microscopes enables cleaning to remove residues of micron order. In addition, after precision cleaning, moisture can be removed by vacuum annealing equipment.