Fine hole processing

- TOP

- Core Technology

- Fine hole processing

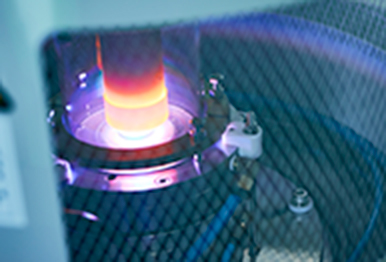

Tool manufacturing

Tool manufacturing technology is the pinnacle of core technology that Kasen nozzle have passed down for over 70 years.

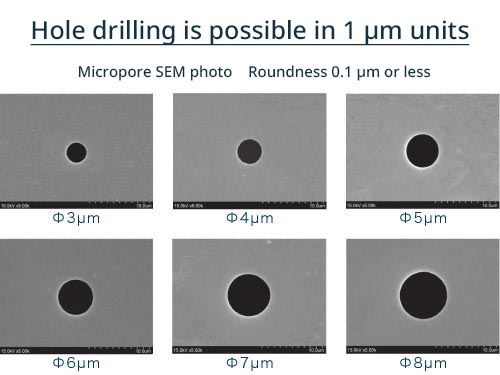

This technology realizes submicron precision hole drilling. Micropores machined with handmade tools achieve hole diameter accuracy, surface roughness, and roundness, which are difficult with other machining methods such as electric discharge, laser, and etching.

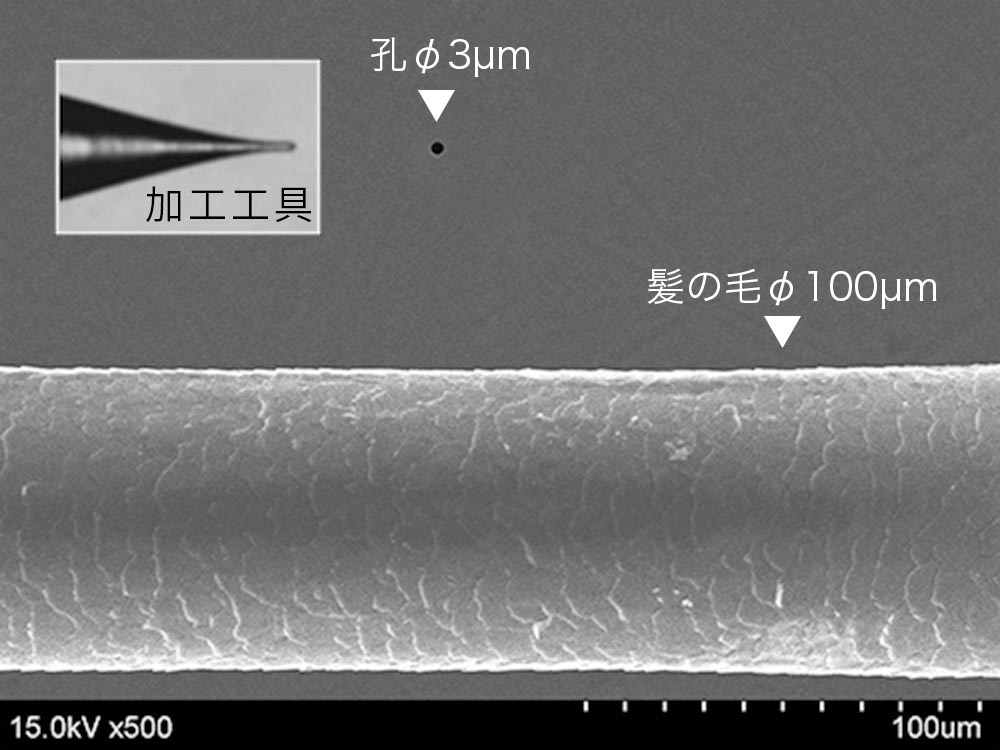

Fine hole processing

Microhole machining is the core technology of the Kasen nozzle that forms the two wheels of tool making. Utilizing fine tools manufactured with submicron accuracy, ultra-high precision hole drilling is realized. As an outstanding low technology, we propose hole machining technology that suits your needs while incorporating advanced technologies such as electric discharge machining and laser machining, centering on plastic working and cutting. It is used for controlling light, air, and fluid as a key part for various applications such as electron beam apertures, industrial inkjets, various orifices, and collimators.

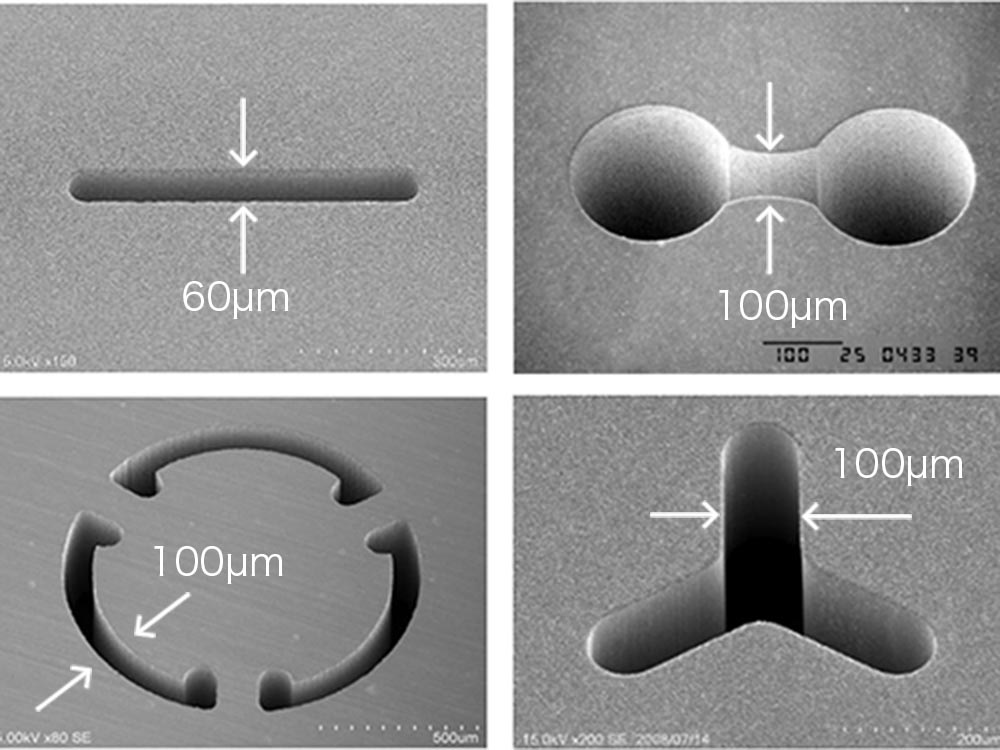

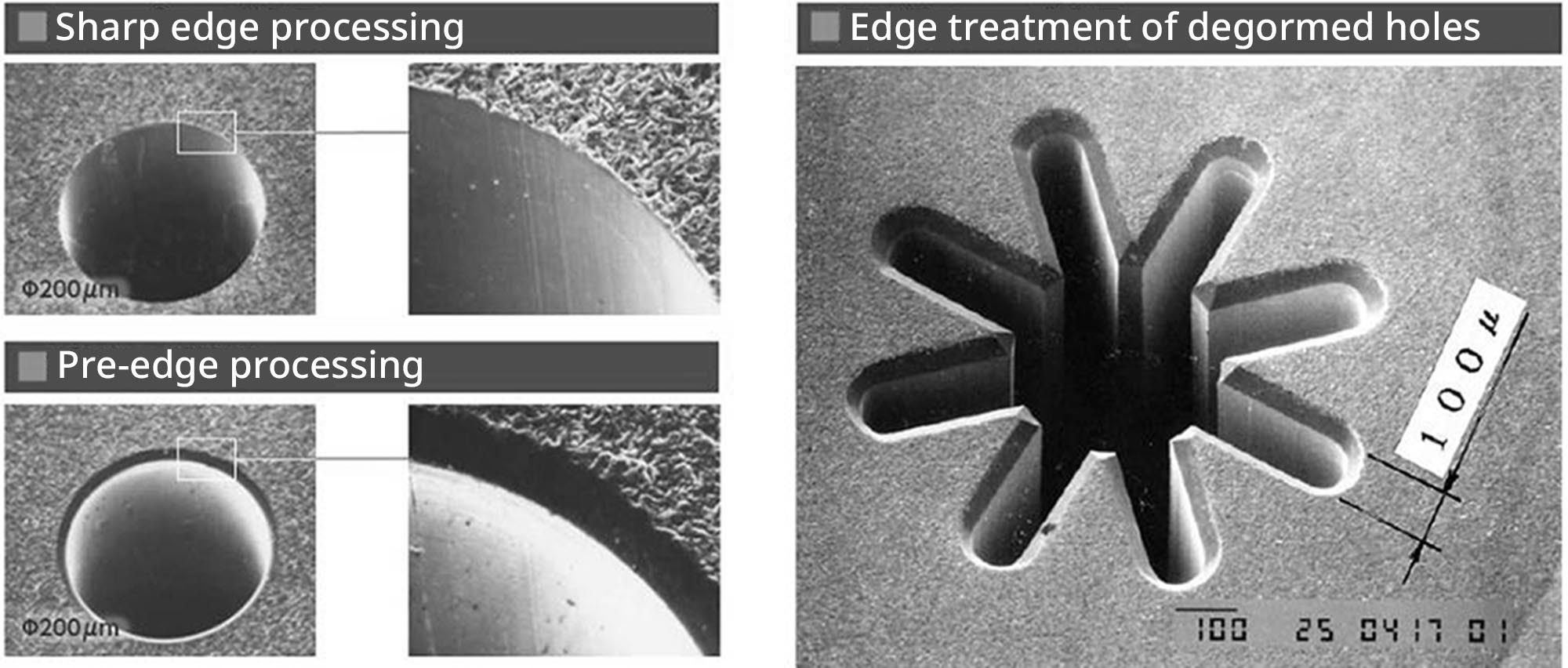

Deformed hole processing

Various deformed holes can be machined on the order of micrometers using our own tools.

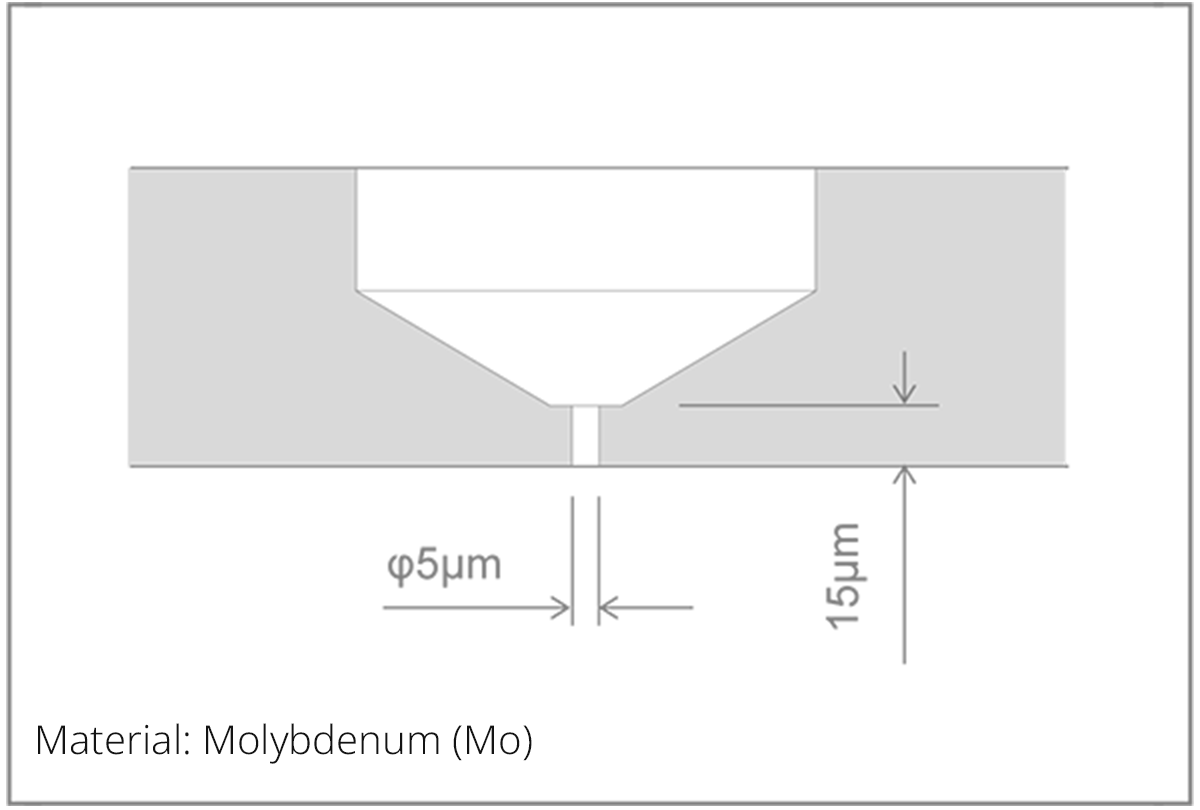

Processable material and minimum hole diameter

We will challenge inexperienced materials and accuracy according to customer's request. The table below shows a part of the manufacturing results, and if you do not have the results, please contact us each time.

| Material | Min.孔径 | |

|---|---|---|

| stainless | 5μm | |

| Structural steel | 10μm | |

| Tool steel | 10μm | |

| "High melting point Highly resistant ingredients |

platinumPt | 0.1μm |

| Gold platinumAu-Pt | 10μm | |

| molybdenumMo | 1μm | |

| TitaniumTi | 2μm | |

| tantalumTa | 5μm | |

| Nickel alloy Alloy-Ni | 10μm | |

| tungstenW | 10μm | |

| Brittle material | siliconSi | 50μm |

| Silicon carbideSiC | 60μm | |

| GlassSiO2 | 10μm | |

| Glassy carbon | 5μm | |

| Machinable ceramics | 30μm | |

| Oxide ceramics | 60μm | |

| plastic | Various | 10μm |

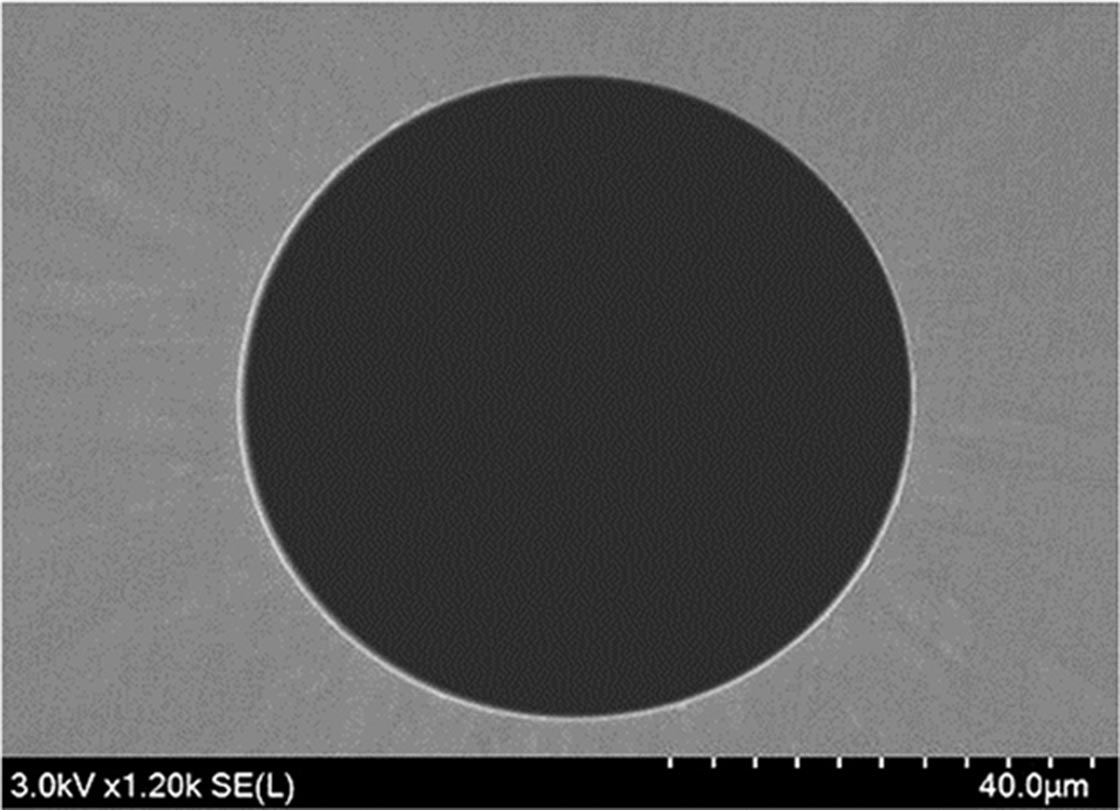

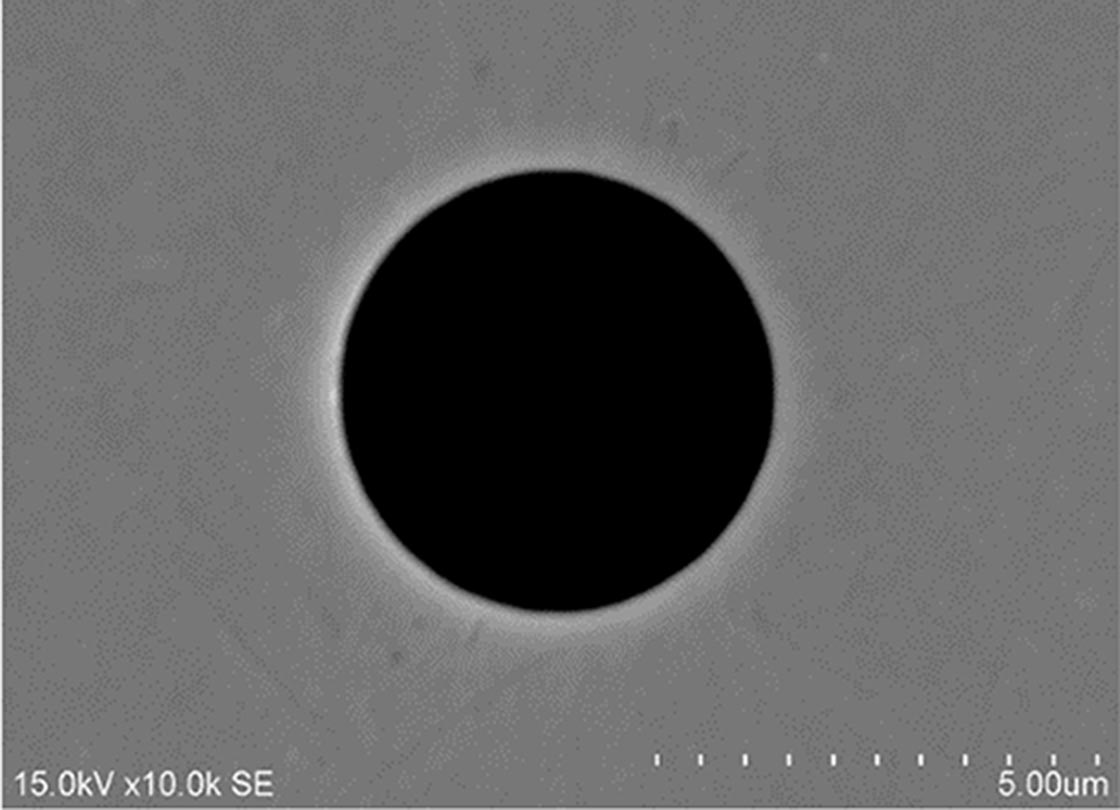

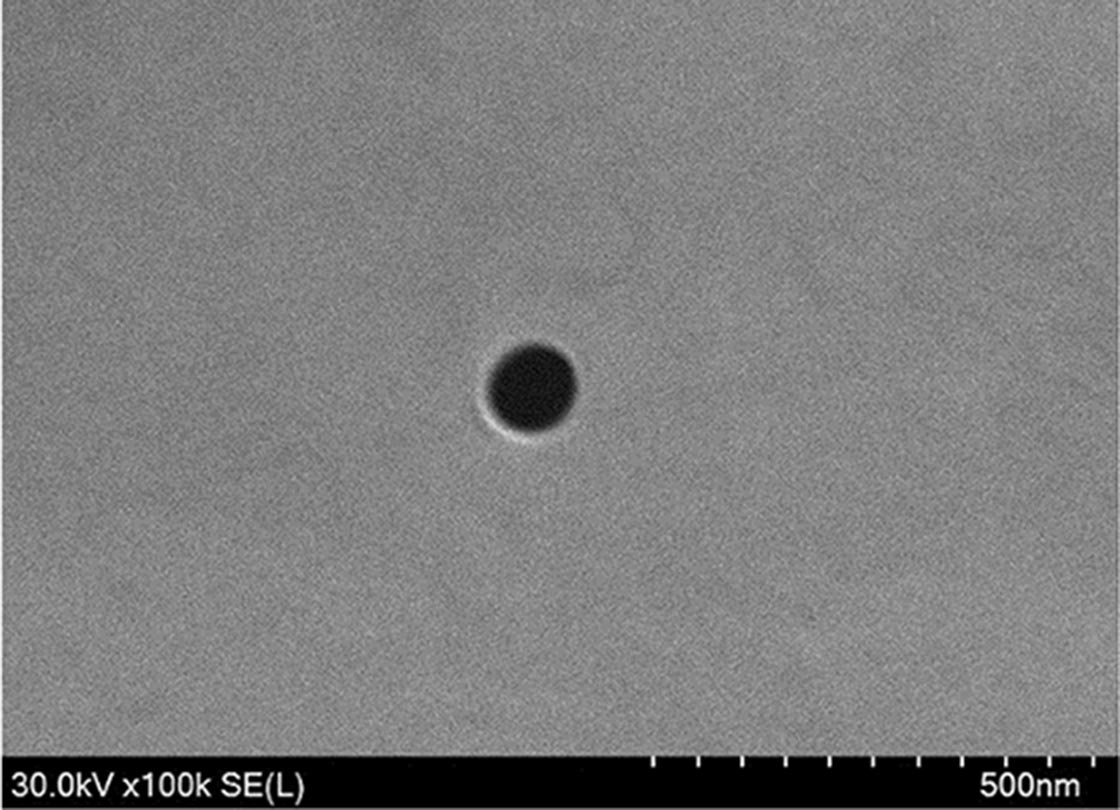

■Sample photo

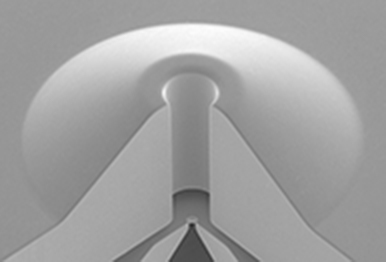

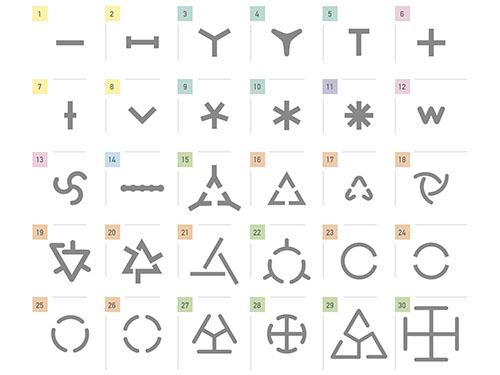

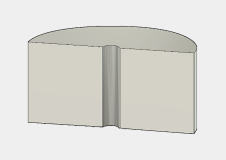

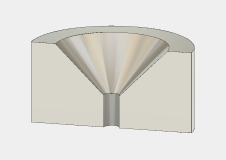

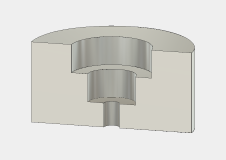

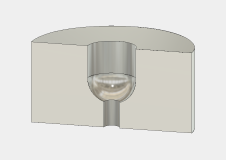

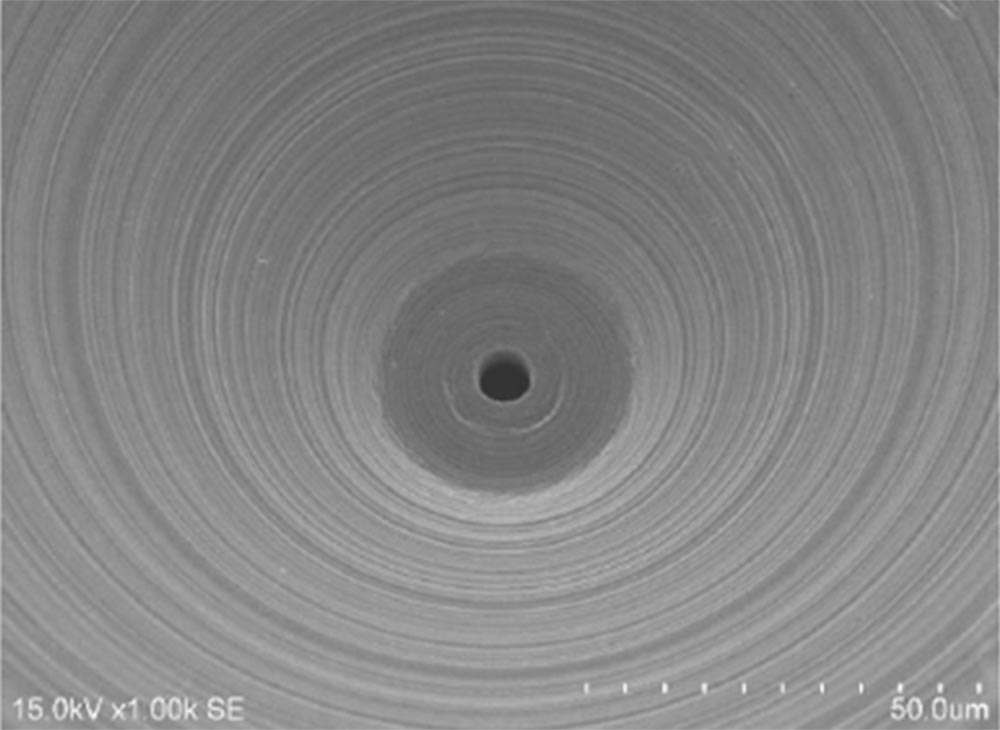

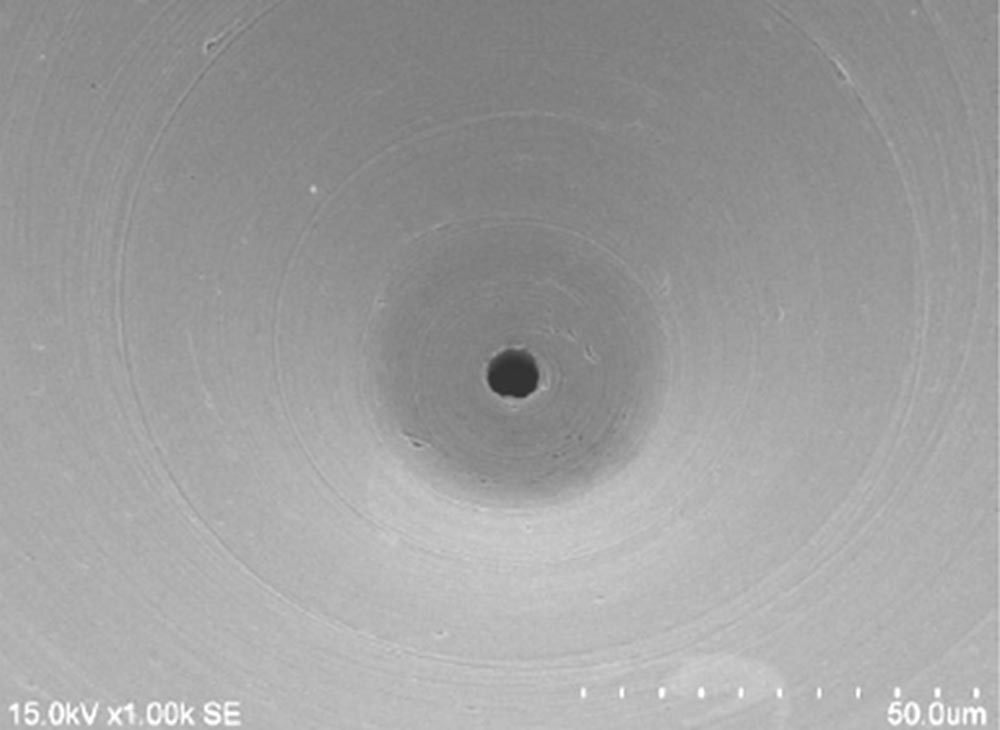

Cross-sectional shape

With the experience cultivated in the design and manufacture of spinning nozzles, we can propose hole shapes suitable for applications and conditions.

Depending on the cross-sectional shape of the hole, we can propose a shape suitable for squeezing the electron beam as well as fluid such as laminar flow, turbulent flow, and pressure loss.

Edge finish

For spinning nozzles, the finish of the hole edges has a significant effect on the quality of the yarn during spinning. We have the technology to finish the edge in R or taper shape as well as the removal of burrs and burrs that we have cultivated over many years in the manufacture of spinning nozzles, so we provide edge treatment that suits the product application and usage conditions. It is possible to.

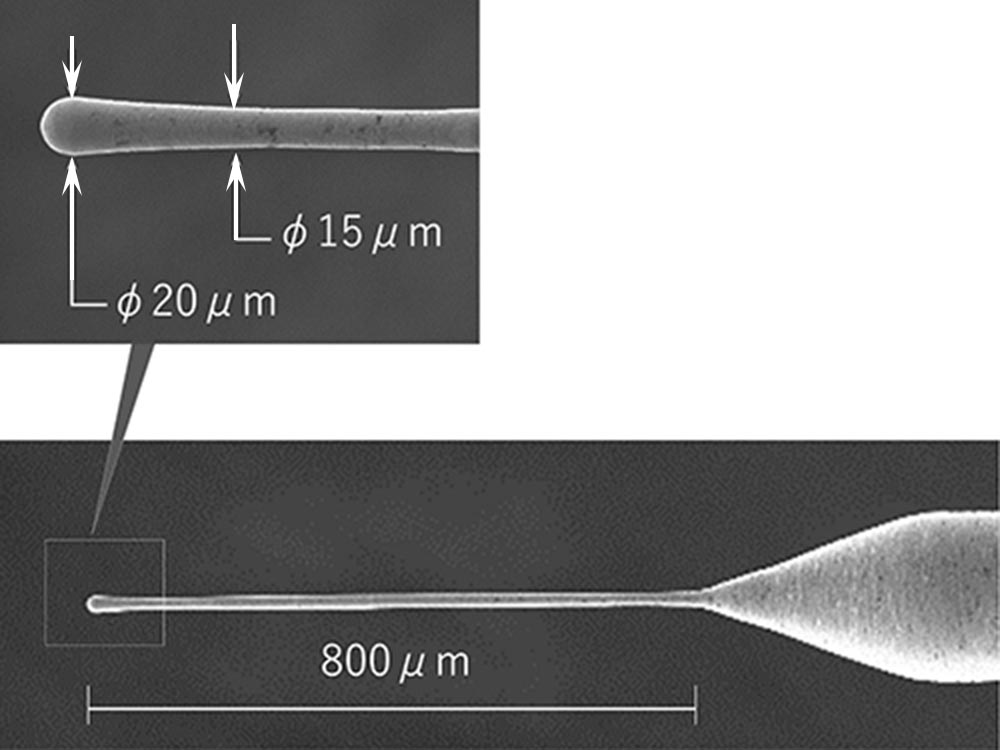

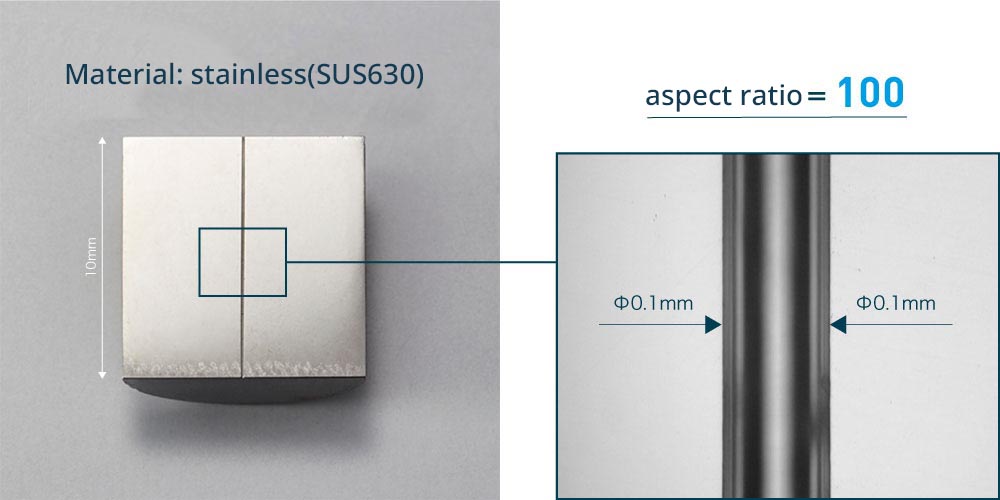

High aspect

In addition to high-aspect hole drilling, we also have high straightness and smooth wall hole drilling technology.

The high mirror surface inside the hole can be finished at a level that is difficult with methods such as laser and electric discharge machining.

- Hole cross section

- Hole cross section (enlarged)