Precision joining

- TOP

- Core Technology

- Precision joining

Precision joining / positioning

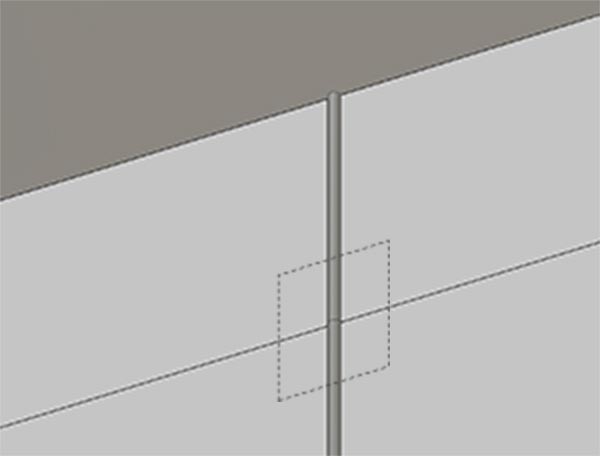

This is a technology for positioning and joining with an accuracy of 1 μm or less. Parts machined with submicron accuracy are combined and joined based on the alignment hole standard.

The joint spacer can be either conductive or non-conductive, and it is possible to select a low outgas type that is intended for use in vacuum.

sample1

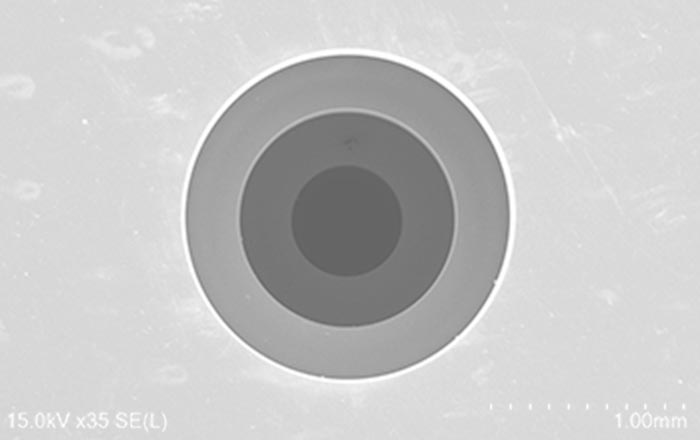

High-aspect holes can be machined relatively easily by finishing the holes after joining multiple plates with prepared holes.

It is possible to finish the inner surface of the hole so that there is no gap between the alignment and the joint surface during joining.

Material: SUS304

Material: SUS304

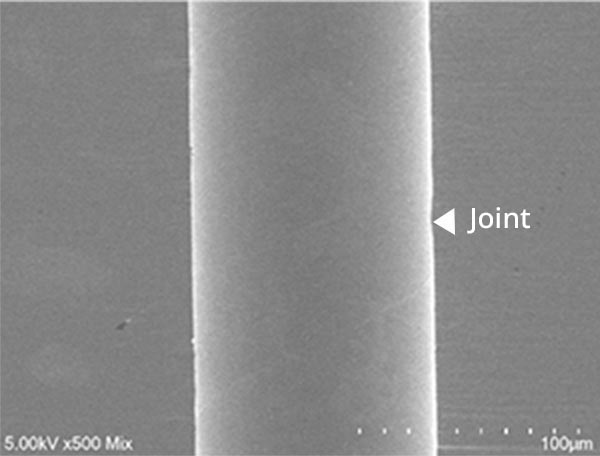

t=6 (3plates of t=2 are joined) Cross section (joint)

Cross section (joint) The inner surface of the hole is so smooth that the joint cannot be confirmed.

The inner surface of the hole is so smooth that the joint cannot be confirmed.

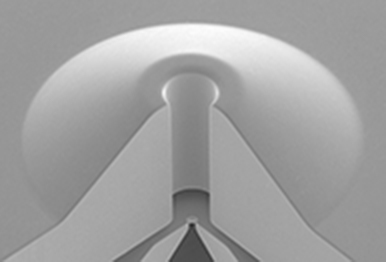

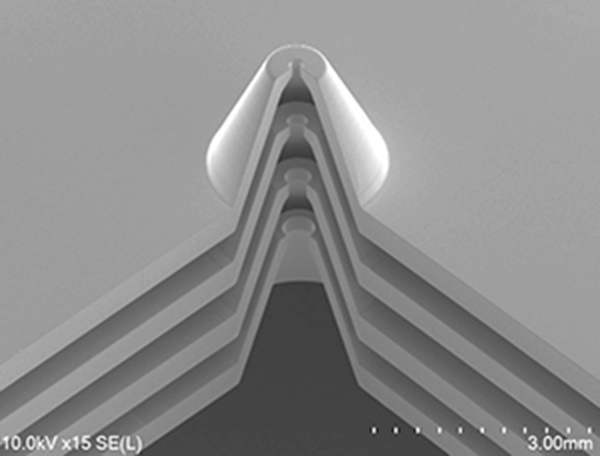

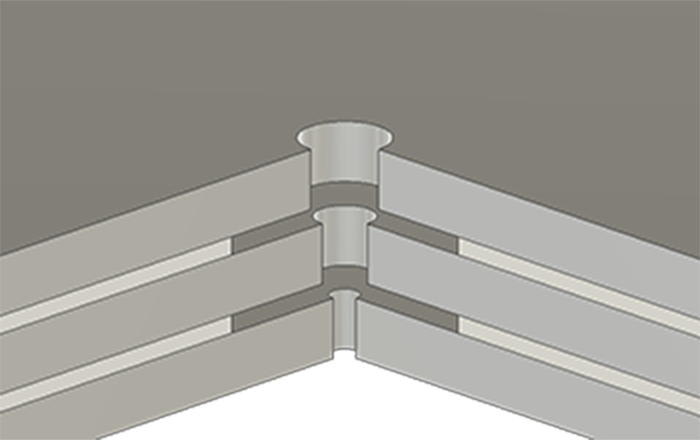

sample2

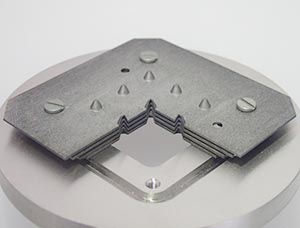

Four molybdenum protrusion plates, each with a hole of φ200 to φ500 µm, are joined with high concentricity.

A gap is secured between each plate with an alumina plate.

Spacer: Alumina(Al2O3)Protruding parts: molybdenum(Mo)

Spacer: Alumina(Al2O3)Protruding parts: molybdenum(Mo)

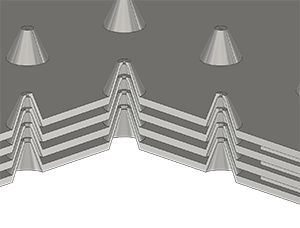

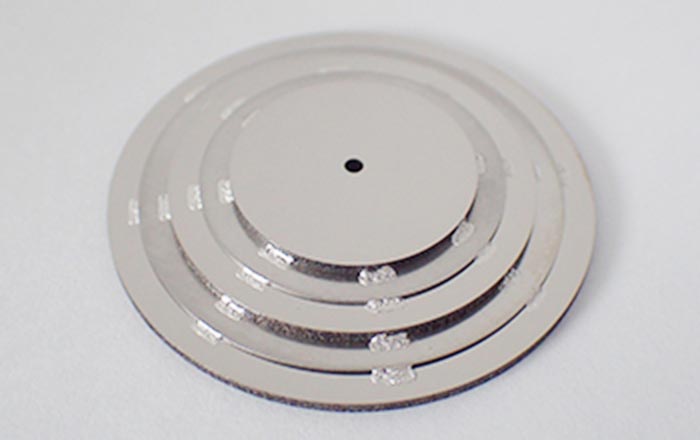

sample3

Three stainless steel plates with holes of φ500 to φ1500 µm are joined with high concentricity.

A gap is secured between each plate with an alumina plate.

Uses conductive adhesive

Uses conductive adhesive Spacer: Alumina(Al2O3)t=0.3mmPlate: Stainless steel (SUS304)t=1mm

Spacer: Alumina(Al2O3)t=0.3mmPlate: Stainless steel (SUS304)t=1mm

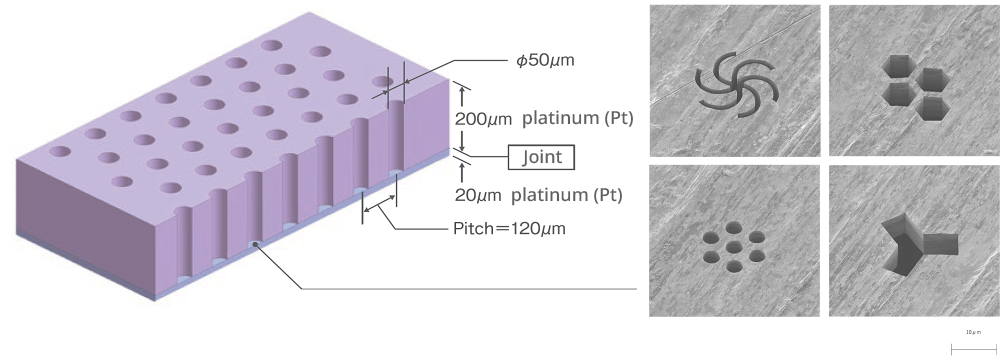

sample4

| Material | platinum(Pt) |

|---|---|

| Features | Machining atypical ultra-fine shaped holes in a thin film |

| Use | Aperture etc. |