Melt-spinning

Melt-spinning

Melt spinning is a typical spinning of synthetic fiber such as Polyester, Nylon, Polypropylene. Melted polymer is discharged from the spinneret.

The discharged fiber is wound after quenching process and drawing process.Melt spinning is used for various polymers and applications.

| Material | Stainless steel / others |

|---|---|

| Application | Textile / Industrial yarn |

| Hole size | Round hole range Φ0.1 to Φ0.3 / Irregular shaped hole |

| Polymer |

|

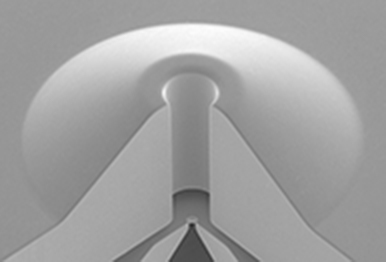

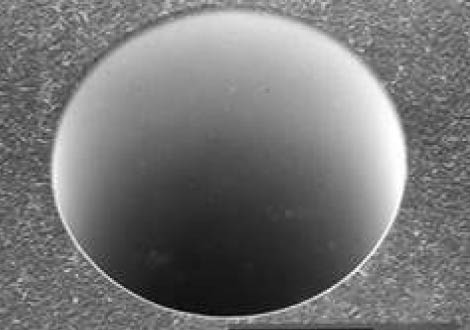

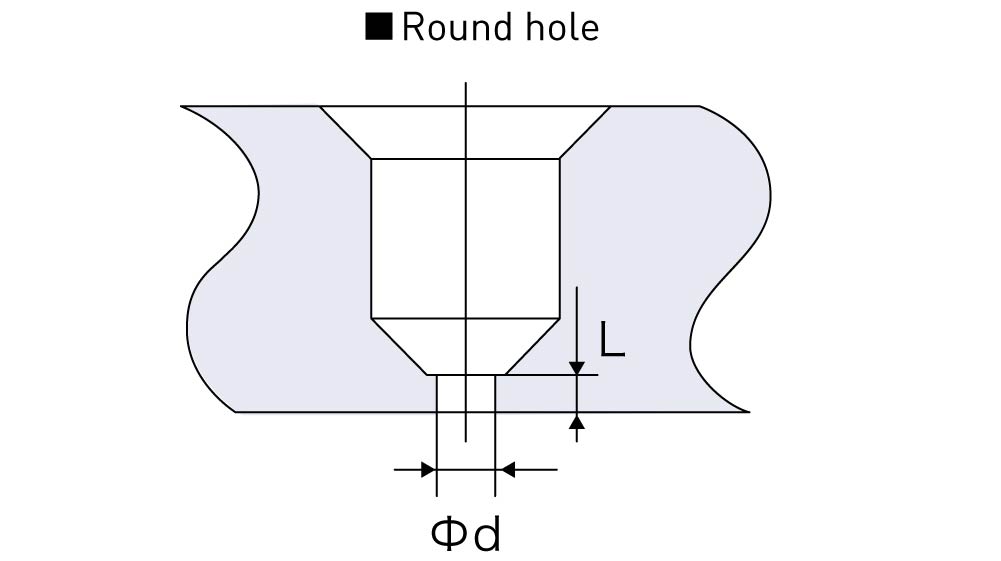

Accuracy of holes for melt spinning use

■Round hole

| Hole diameter | L/d | Accuracy of hole diameter | Accuracy of capillary length | ||

|---|---|---|---|---|---|

| Special | Standard | Special | Standard | ||

| Φ0.07~Φ1.0 | 1/1~5/1 | ±0.001 | ±0.002 | ±0.01 | ±0.02 |

| Φ1.1~Φ2.0 | 1/1~20/1 | ±0.003 | ±0.005 | ±0.02 | ±0.03 |

| Φ2.1~ | 1/1~30/1 | ±0.003 | ±0.005 | ±0.02 | ±0.03 |

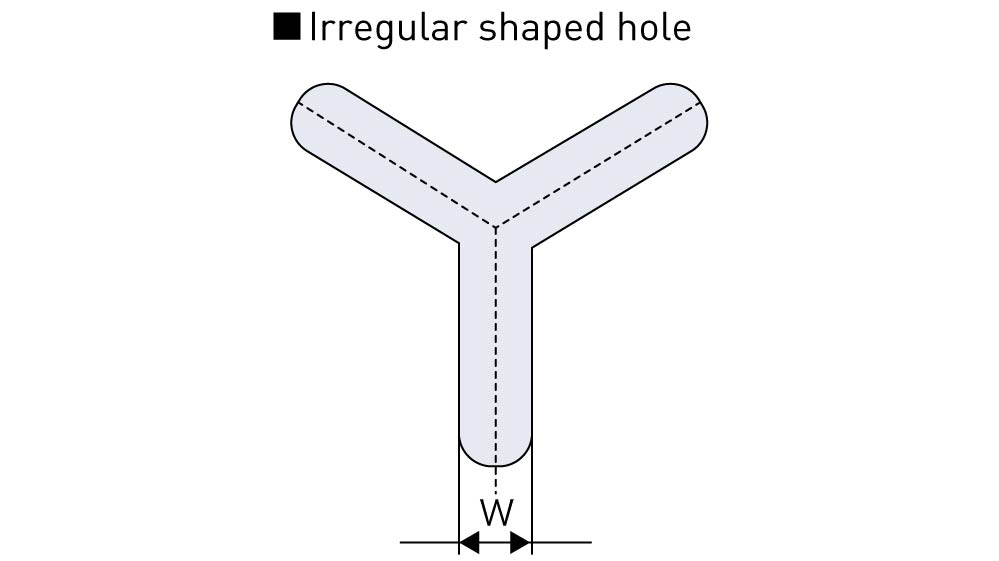

■Irregular shaped hole

| Slit width | L/W | Accuracy of slit width | Aaccuracy of capillary length | ||

|---|---|---|---|---|---|

| Special | Standard | Special | Standard | ||

| 0.04W~0.1W | 1/1~18/1 | ±0.001 | ±0.002 | ±0.01 | ±0.02 |

| 0.11W~0.8W | 1/1~20/1 | ||||

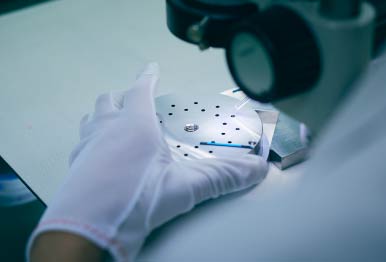

Special Treatment on Surface

By coating on the nozzle surface, various performance can be given.Optimum coating materials can be selected depending on the raw materials used, spinning and cleaning condition.

It also contributes to cost saving such as extended life time and maintenance during operation.

■Typical example of coating we can make

| coating with single element | coating with mixed plural elements | special coating | ||||||

|---|---|---|---|---|---|---|---|---|

| Cr | Si | TiN | CrN | Si3N4 | TiC | SiC | T7 | |

| surface roughness | depending on surface roughness of base material | ← | ← | ← | ← | ← | ← | ← |

| hardness | HV500 | HV700 | HV2300 | HV1900 | HV1300 | HV2500 | HV2000 | HV2300 |

| coating thickness | 0.1~5um | ← | ← | ← | ← | ← | ← | ← |

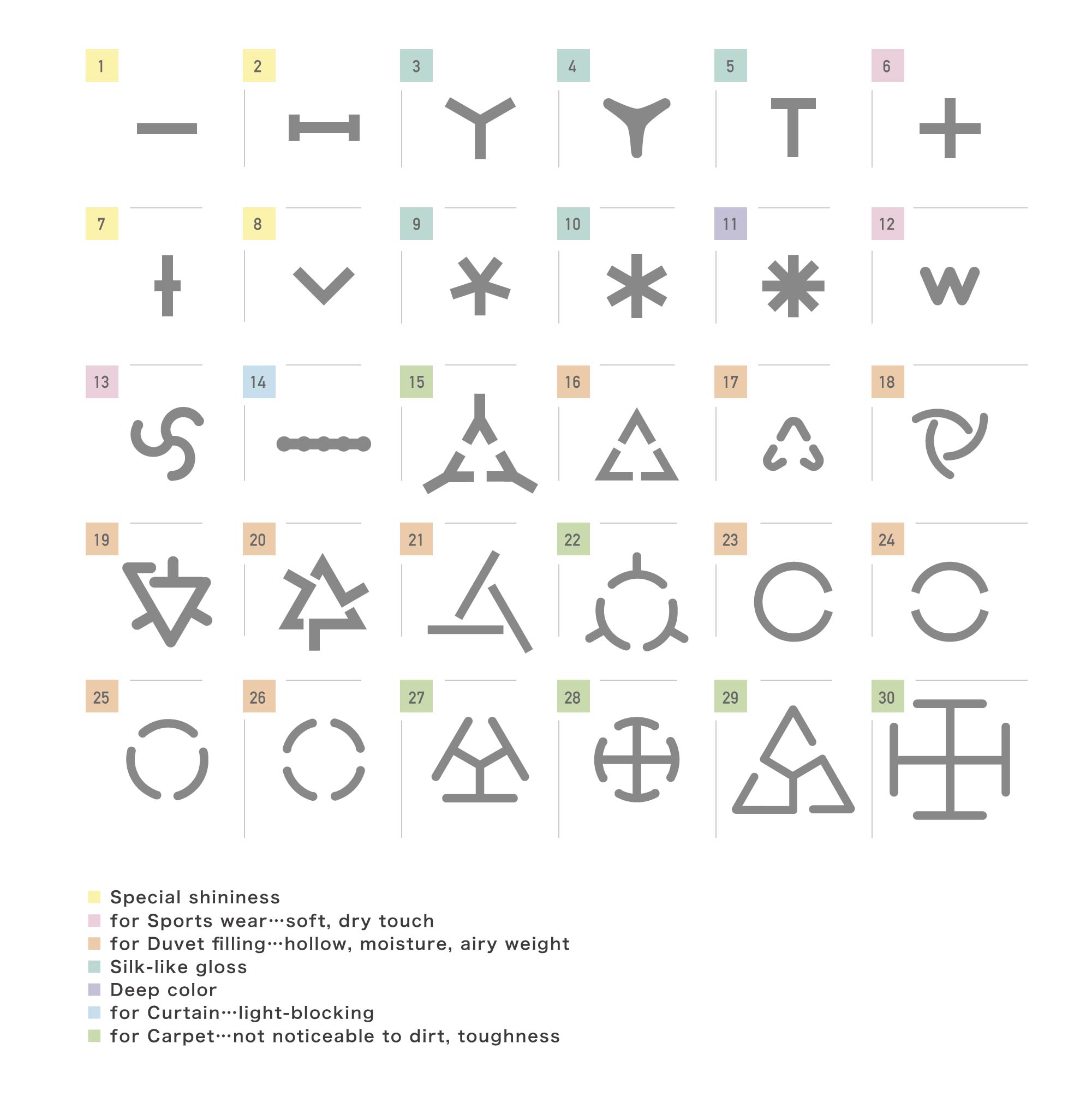

List of irregular shaped hole

By changing polymer combination and spinning condition, fiber spun from irregular shaped hole can obtain various type of characteristic. The hole shape is selected based on required performances.

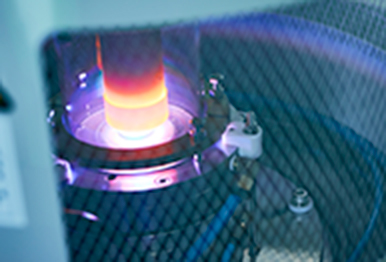

Pilot machine

Our pilot melt spinning machine is for POY and SDY processes test by thermoplastic polymer like PET, PA and PO. It is able to spin by not only single polymer but 2 or 3 types of polymers simultaneously to produce a conjugated fiber.

| Extruder | φ25/φ30/φ35 |

|---|---|

| Spinning temperature | Max. 330℃ |

| Godet roller #1 | 1,000-4,000m/min, 50-150℃ |

| Godet roller #2 | 1,000-6,000m/min, 50-150℃ |

| Winder | 2,000-6,000m/min |